The moisture content sensitivity of different strength properties |

Boxcomp Help Index Main Index |

Different properties of corrugated board and its components have different sensitivities to changes in moisture content. In general, the compression strength properties are very sensitive to moisture content variations. A good rule of thumb is that if the moisture content of the material is increased by 1% the compression strength is decreased by 8%. A change in moisture content of approximately 1% is associated with a change in relative humidity from about 50% to 60%.

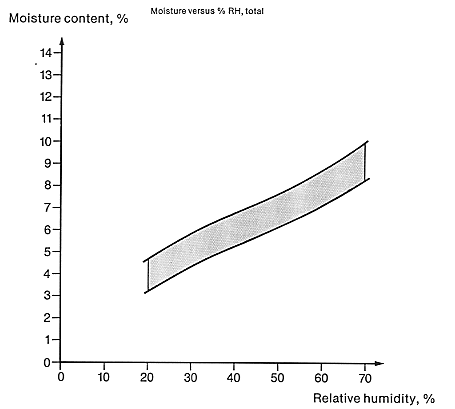

In connection with the development of the SCT test apparatus (STFI shortspan compression tester 53-M), automatic compensation of the compression strength is achieved by simultaneous testing of the moisture content, an extensive investigation of the moisture content sensitivity was carried out. The investigation involved the testing of a total of 36 different kraft liner and test liner grades from 9 different paper mills. The change in strength of the investigated grades, per percentage unit change in moisture content, varied from 7.1 to 10.2%,with a mean value of 8.3%. The equilibrium moisture content for the different materials at 23°C and 50 % RH after preconditioning the material at 23°C and 20% RH lies between 6.0% and 7.5%. No great difference in equilibrium moisture content between kraft liner and test liner could be detected. There was possibly a tendency for the equilibrium moisture content of the kraft liner to be about 0.5% higher which is probably expected.

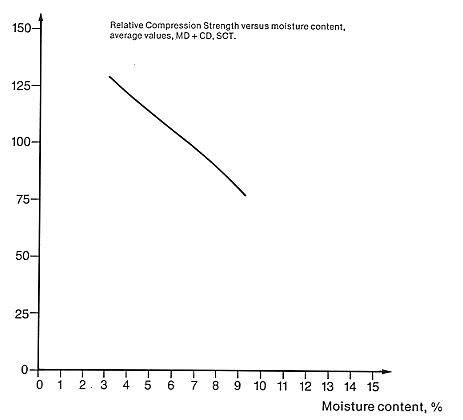

Other strength properties which are strongly affected by the moisture content are the tensile stiffness and thus also the bending stiffness of corrugated board. The least moisture sensitive property of liner and corrugated board, in the range of 30% - 70% RH, is probably the bursting strength, where only moderate strength variations arise. The compression strength of liner and fluting as a function of moisture content in %.

The compression strength at 50% RH has been set to 100 for all grades. (See below)

Values of the moisture content of 36 different liner and fluting grades as a function of the relative humidity.

Conclusion

The strength of a corrugated board box is affected indirectly by the atmospheric conditions. It is the actual moisture content in the board which directly determines its strength.A corrugated board material reaches different moisture contents depending on the atmosphere and also on its prehistory, because of the moisture hysteresis effect.

The equilibrium moisture content of most liner and fluting materials at 23°C, 50% RH, is found to be between 6 and 7.5% measured after pre-conditioning at 23°C and 20% RH.

The compression strength is very sensitive to the moisture content. As a rule of thumb it can be said that the strength decreases by 8% if the moisture content increases by 1% unit. The rule of thumb is however valid only within approximately 4% of the equilibrium moisture content at 23°C, 50% RH.