Measuring Samples |

Boxcomp Help Index Main Index |

MEASURING COMPETITORS SAMPLE PACKS

Often a design department is given a sample of a pack the customer is receiving, rather than the full size, style and board grade information. It is then necessary to analyse this sample, to obtain then relevant information.

Finding the inside size of standard 0200 series packs

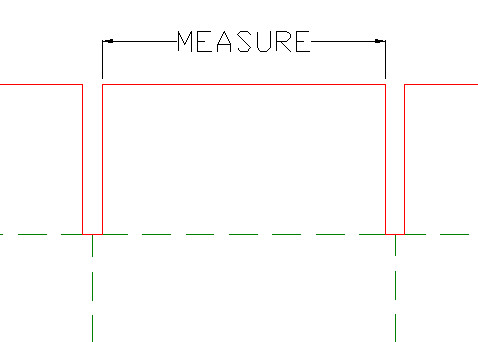

The pack's flange should be opened up, taking care to do as little damage as possible. The pack should then be laid out on a large table and the bend to bend distances measured. Only measure panels 2 and 3. If variation is going to occur on a pack, then it will most likely be in panels 1 and 4. Make sure that you write your measurements down, on the pack itself, in the panels that they relate to. This will make cross-checking easier.

The necessary information should then be filled in, on the pack analysis sheet. Remember, these are BEND TO BEND SIZES. Allowances must be SUBTRACTED from them, to find the pack's inside size.

Any other relevant information should also be filled in, on the analysis sheet. This could be notes on hand-hole positioning, vent holes, fitment details etc.

Always remember to cross-check your inside size with the blank size of the pack, by adding the relevant inside sizes and allowances together and seeing how close they come to the pack's blank size. If they are more than 3mm out you should re-check your figures.

When finding a pack size it is usual to work from the inner most element. Therefore, if you have a case with divisions, you would measure the divisions' cell size and calculate the case size from that. Similarly for 4 and 5 panel liners, etc. Again this should reduce the effects of size variation due to production tolerances. The only exception to this being simple pads, whose size is not normally rigorously controlled.

Finding a case size without damaging a pack

Occasionally a customer will require a sample to be measured, but will not allow the sample to be destroyed. Therefore we will not be able to open up it's flange. It is then necessary to use a little lateral thinking and measure the flaps instead. Slots are almost always centred on the panel bends. This means that by measuring the size of the slot (normally either 6mm or 10mm) and relating this to the slotted size of the flap and then panel allowances, it is possible to calculate the panel sizes.

FINDING THE INSIDE SIZE OF STANDARD 0200 SERIES PACKS

| 6mm slots | 10mm slots | |

| B flute | Flap + 3 | Flap + 7 |

| C flute | Flap + 1 | Flap + 5 |

| BC flute | Flap - 1 | Flap + 3 |

By folding back the flaps the depth bend to bend size can be measured in the normal way, without causing damage to the pack.

It should be noted that this method of measuring is less accurate and more open to error. Therefore it should only be used when necessary.

Finding the inside size of Die-cut packs

Again a similar process is used for analysing die-cut samples. The allowances for all standard die-cuts are within your design manual. Occasionally the allowance for a non-standard die-cut design will need to be calculated.It is difficult to cross-check the blank size of a die-cut by simple calculation. However, your finished drawing's blank size should always be checked against the blank size of the pack.

Finding the Board Grade of a pack

In the normal course of events, a board grade is found using the chemical weighing scales. A 100 x 100mm sample is taken (making sure not to take an area which is printed) and weighed. The liners are split apart and also weighed, then individual totals are added up and compared with the original total weight. Experience must be used in telling the difference between Kraft, Test and BDC (Test 4).The draw factors for the various types of fluting are as follows:

B flute = 1.35

E flute = 1.29

C flute = 1.45

A flute = 1.55

After the fluting weight you have measured is divided by the draw factor, 10 should then be subtracted for corrugator adhesive. This then gives you the true weight of the fluting.

Finding the Board Grade of a pack without badly damaging it

It is possible to find the weight of a piece of material by measuring its caliper. This can be done with a micrometer.The reading is usually taken it tens of microns and then this figure is divided by 0.15, to give the approximate weight of the liner or fluting.

Care must be taken when cutting the thin sliver of liner, from between the fluting arches, not to get a sample with corrugator adhesive on it. Naturally, this is a less accurate method of finding a board grade and should be avoided wherever possible.